Canada Appeals for International Firefighting Aid

June 09, 2025: Canada has issued an international appeal for firefighting support as wildfires intensify across multiple provinces

March 28, 2022: -Russia’s war in Ukraine could see the production of neon, a critical gas in advanced semiconductor manufacturing, fall to worryingly low levels when the world is already grappling with a chip shortage.

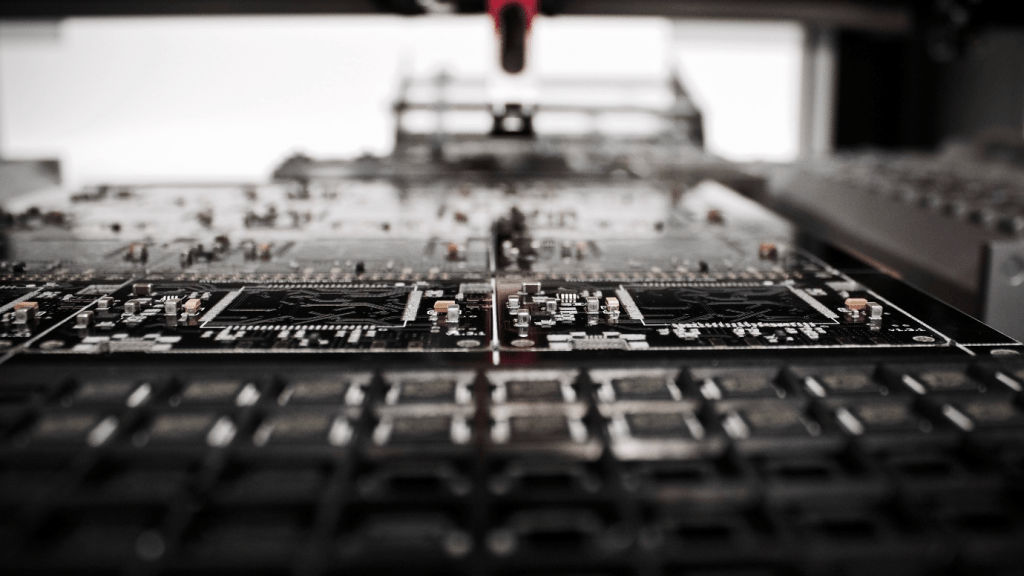

Neon is required for the lasers used in a chip production process called lithography, where machines carve patterns onto small pieces of silicon made by the likes of Samsung, Intel, and TSMC.

According to Peter Hanbury, a semiconductor analyst at research firm Bain & Co, over half of the world’s neon is produced by a handful of companies in Ukraine. According to Peter Hanbury, a semiconductor analyst at research firm Bain & Co.

Those companies include Mariupol-based Ingas and Cryoin and Iceblick, which are based in Odesa.

Still, Ingas and Cryoin have ceased operations in recent weeks amid attacks from Russian forces.

With world-leading Ukrainian firms that shuttered their operations, neon production will fall off a cliff as the conflict drags on.

Based on estimates from consultancy firm TechNet, worldwide neon consumption for semiconductor production reached roughly 540 metric tons in the process year. Given Ukraine produces over half of the world’s neon, the figure could fall below 270 metric tons in 2022 if the nation’s neon producers remain shut.

“Of the materials used in chip-making that could see a hit to their supply from the Ukraine conflict, neon poses the greatest potential challenge,” Hanbury told CNBC through an email.

The ongoing global chip shortage has already wreaked havoc on supply chains and led to lengthy delays for products such as new cars and games consoles like the PlayStation 5.

A potential global neon shortage threatens to make matters even worse.

We provide the insights on leaders who are responsible for taking their organization to new heights, all the while bringing together a group of talented individuals.

June 09, 2025: Canada has issued an international appeal for firefighting support as wildfires intensify across multiple provinces

May 27, 2025: Air Canada Cuts Five U.S. Routes for Winter 2025–26, Part of Broader Cross-Border Retrenchment

May 26, 2025: Trump Freezes $2.2B in Federal Grants to Harvard Over DEI, Threatens Tax-Exempt Status.

May 14, 2025: Microsoft has announced plans to reduce its global workforce by approximately 3%, affecting roughly 10,000 employees across multiple departments.

May 13, 2025: The Trump administration is considering suspending the constitutional right of habeas corpus in a bid to accelerate mass deportations.

April 29, 2025: Donald Trump’s second term has reached the 100-day mark under sustained public skepticism, with national approval ratings