Canada Appeals for International Firefighting Aid

June 09, 2025: Canada has issued an international appeal for firefighting support as wildfires intensify across multiple provinces

March 3, 2021: SpaceX is planning to build a new factory in Austin, Texas, that expands the region even more from one of Elon Musk’s companies after moving there last year.

The facility’s plan was revealed in a company job posting, which seeks an engineer for its Starlink satellite internet division.

“To keep up with global demand, SpaceX is breaking ground on a new, state-of-the-art manufacturing facility in Austin,” the company said in the posting.

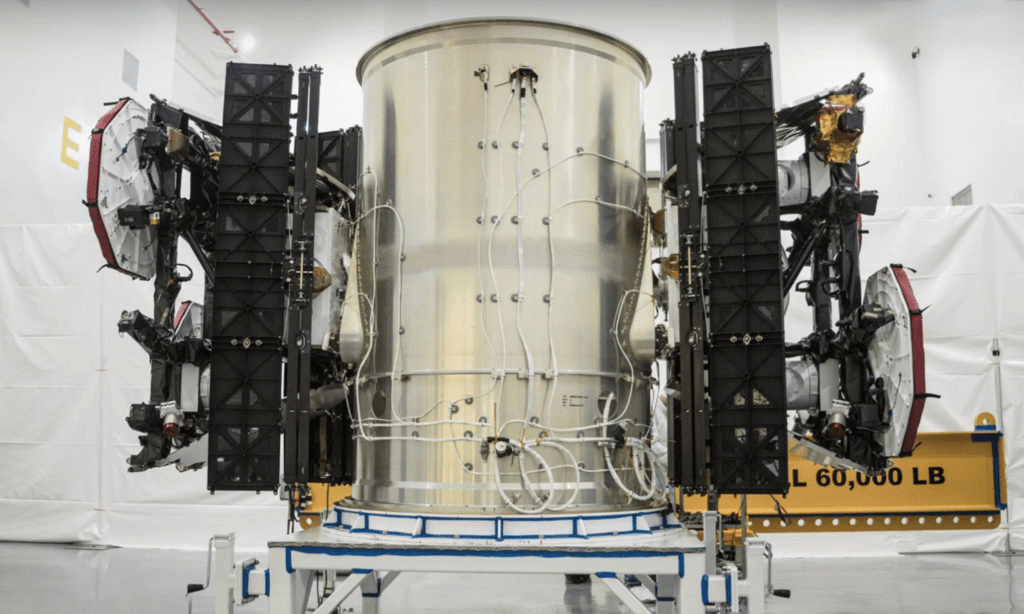

SpaceX notes that the factory is designed for “high volume manufacturing,” specifically to make “millions of consumers facing devices.” For its satellite internet network, those devices are known as the Starlink Kit, which includes an antenna that connects to the satellites, Wi-Fi routers, and antenna mounting hardware

The company’s Starlink unit is currently based in Redmond, Washington – a few miles east of Seattle. The Redmond facility has developed and produced Starlink equipment to date, with the company building upwards of 120 satellites each month.

Austin-based NBC affiliate KXAN first reported SpaceX’s plans for the new factory.

Starlink is the company’s capital-intensive project to build an interconnected internet network with many satellites, known in the space industry as a constellation, designed to deliver high-speed internet to consumers anywhere on the planet.

To date, SpaceX has launched above 1,000 satellites for Starlink. SpaceX began rolling out early service in a public beta to customers in the U.S., Canada, and the U.K., with service priced at $99 a month, plus a $499 upfront cost for the hardware needed to connect to the network.

The job posting did not supply any further details on the Austin factory, such as square feet, when expected to become operational, or its intended production goals. SpaceX’s posting did note that the role including working remotely in Austin and traveling about a quarter of the time to SpaceX’s headquarters in Los Angeles “until Austin facility is fully established.”

We provide the insights on leaders who are responsible for taking their organization to new heights, all the while bringing together a group of talented individuals.

June 09, 2025: Canada has issued an international appeal for firefighting support as wildfires intensify across multiple provinces

May 27, 2025: Air Canada Cuts Five U.S. Routes for Winter 2025–26, Part of Broader Cross-Border Retrenchment

May 26, 2025: Trump Freezes $2.2B in Federal Grants to Harvard Over DEI, Threatens Tax-Exempt Status.

May 14, 2025: Microsoft has announced plans to reduce its global workforce by approximately 3%, affecting roughly 10,000 employees across multiple departments.

May 13, 2025: The Trump administration is considering suspending the constitutional right of habeas corpus in a bid to accelerate mass deportations.

April 29, 2025: Donald Trump’s second term has reached the 100-day mark under sustained public skepticism, with national approval ratings