- March 5, 2026 6:58 pm

- California

Disruptions such as COVID-19, war, and climate changes have exacerbated the challenges of managing congested yards and ports, highlighting notorious manual operations inefficiencies and costs.

The lack of real-time visibility in supply chain management is one of the most significant challenges companies face. Without instant access to information about their operations, most businesses rely on manual processes, which are time-consuming and prone to error.

Nuvoola is a, AI-based SaaS solution provider that drives operational performance through automation and real-time visibility. Thanks to their expertise in computer vision, data integration, and data prediction, they can capture and exploit data from multiple sources, like cameras and IT systems, to provide real-time visibility on a site’s operations and merchandise movement.

Supply chain companies are rich in data but lack the tools to exploit it. They have cameras, but they don’t have the tools to exploit what the cameras see, like trailers, trucks, and container identification numbers. They get information from carriers but have difficulty centralizing it because their processes rely primarily on paper and manual steps. These companies have a vast untapped potential to increase operational efficiency through artificial intelligence. Nuvoola integrates all these information sources, extracts the relevant data to centralize it, and leverages it to improve operational efficiency.

Under the aegis of Martin Renière, Founder and CEO of Nuvoola, the company has witnessed unprecedented growth, thanks to his passion for innovation and technology, which is infectious and apparent to anyone who has worked with him. He is inherently curious and always looking for new ways to leverage the power of innovation. As a successful entrepreneur for over 20 years, he is experienced in bringing new solutions to the market and driving his companies to grow and advance using the latest technologies. Martin’s passion for innovation and technology is infectious and apparent to anyone who has worked with him.

A Unique Solution

Nuvoola’s LUKE AI for Manufacturing and Distribution Centers is an intelligent process optimization solution to streamline yard operations and increase logistics efficiency. The complete solution comprises a reservation system for carriers to schedule their time of arrival, an automated check-in and security process for truck drivers, and an intelligent dashboard that displays operational insights and performance indicators.

With its self-serve reservation feature, carriers and shippers can schedule an appointment allowing the site to optimize its operation logistics and increase dock workers’ productivity by synchronizing appointment requests with dock or terminal capacity.

Easily integrated into existing camera infrastructure, LUKE AI for MDC uses computer vision to digitize and centralize information in real-time such as the arrivals and departures of trucks, trailers, and containers, purchase orders, and seal numbers. For example, when a shipment arrives, the system uses the cameras at the gate automatically detect and identify drivers, trucks, trailers and containers that enter or exit the site. All the information is captured and centralized into LUKE’s platform, giving organizations full visibility on what comes in and out of their site. The SaaS solution can also include an intelligent self-serve kiosk installed at the gate to automate driver’s identification and vehicle identification. If the driver is authorized to enter the site, the process only takes a few seconds. It reduces check-in time while providing secured access to the site without the need to have someone at each gate. The kiosks can also interact with the drivers, telling them where to go once identified. Paired with the reservation system, this improves the flow of operations while decreasing gate congestion and reducing dwell time.

The solution also generates operational performance indicators in real-time via customizable multi-site dashboards to quickly identify opportunities to increase efficiency and reduce costs.

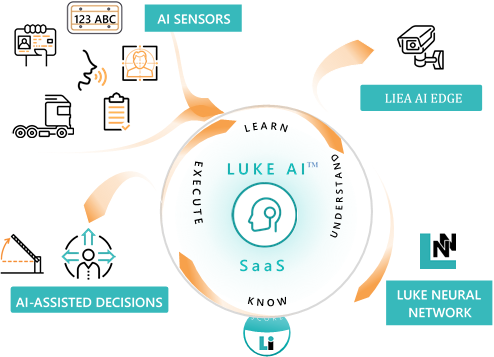

LUKE AI is Nuvoola’s AI engine at the heart of all of its SaaS solutions and serves as a platform to develop advanced machine learning models to automate manual tasks. Mainly because they use computer vision to capture data from cameras and turn it into actionable intelligence.

LUKE stands for Learn, Understand, Know and Execute.

Learn: The system acquires license plate and vehicle images, the face of a driver, employee or visitor, an employee card, driver’s license, and other documents, thanks to the camera video feed. It can also use data from other sources, such as internal management systems.

Understand: The system creates or validates profiles by recognizing faces and voices, recording language preferences and associating driver’s license information. It trains multi-factor AI models for future identification of individuals on the first visit. It verifies if the PO number, date and time, driver, company, cab and trailer match valid combinations in the business rules engine database.

Know: The LUKE™ Neural Network assesses the validity of all variables taken together and determines if the person should be given access using a comprehensive confidence score. It compares the data capture with existing data to validate. It stores all data and presents it on an intelligent, customizable dashboard.

Execute: The system assesses the next step and takes appropriate action; for example, it can let a person pass or alert personnel to intervene, if necessary.

In the supply chain sectors, the LUKE AI platform is an AI-powered solution that learns how an organization’s supply chain works and gives them access to accurate, real-time information. “You gain transparency and visibility to make better-informed decisions.”

Serving Clients with Best Solutions

In an instance, AGD Verchères was looking for an innovative solution to increase operational performance in its yard while having visibility on everything that came in and out of its site. Plus, they wanted the solution to help them with asset management.

Nuvoola first digitized the business processes and automated the site’s shipping container inventory.

Using a high-resolution camera connected to the 5G network, Nuvoola easily captures all the identification information about containers, trucks, and trailers entering and exiting the facility. It helped AGD Verchères gain visibility on their clients’ assets stored in their facility.

Thanks to Nuvoola’s solution, AGD Verchères was able to increase operational visibility by obtaining real-time data on a dashboard that facilitates the analysis of key performance indicators and enables better-informed decision-making.

Nuvoola AI’s expansion plan includes helping seaports be more resilient – Nuvoola is currently working with seaports to increase visibility, fluidity and resilience. Their goal in 2022 is to make Canadian ports more efficient and more resilient. All supply chain actors face a significant increase in the level of risk associated with major disruptors. LUKE AI for Supply Chain and Logistics has evolved to provide seaports with strategic information and predictive analytics on supply chain velocity, fluidity, and short-term resilience.

Nuvoola’s analytics tools focus on understanding the gateway-wide impacts of events, developing a near-real-time warning system related to specific resilience disruptors, and recommending potential actions that could guide gateway participants in their recovery actions leading to a return to full-scale operations.

"Thanks to our expertise in computer vision, data integration, and data prediction, we can capture and exploit data from multiple sources, like cameras, IT systems, and public databases, to provide real-time visibility on a site’s operations and merchandise movement."

Martin Renière

Founder and CEO