Canada Appeals for International Firefighting Aid

June 09, 2025: Canada has issued an international appeal for firefighting support as wildfires intensify across multiple provinces

May 5, 2022: -On Tuesday, the head of the National Aeronautics and Space Administration (NASA) discussed a dramatic shift in how the agency is planning to issue contracts for its space exploration programs, which cited success with cost-saving competitive bids.

NASA administrator Bill Nelson, who testifies before a Senate subcommittee on the agency’s budget for landing astronauts on the moon, strongly backed fixed-price contracts with companies and decried more variable cost-plus agreements as “a plague” on the agency.

Nelson’s emphasis on competition represents a boon for the growing swath of space companies looking to provide low-cost services to NASA and a sharp curtailing for aerospace and defense contractors that traditionally benefited from cost-plus deals.

Fixed-price contracts set a maximum payout for a good or service, while cost-plus agreements result in the government paying for the cost of the work, plus additional fees, which can balloon throughout the project.

The most significant difference between the contract structures is who picks up the bill for delays or cost overruns: fixed-price assumes the companies building the systems absorb any unanticipated expenses, while cost-plus leaves NASA on the hook.

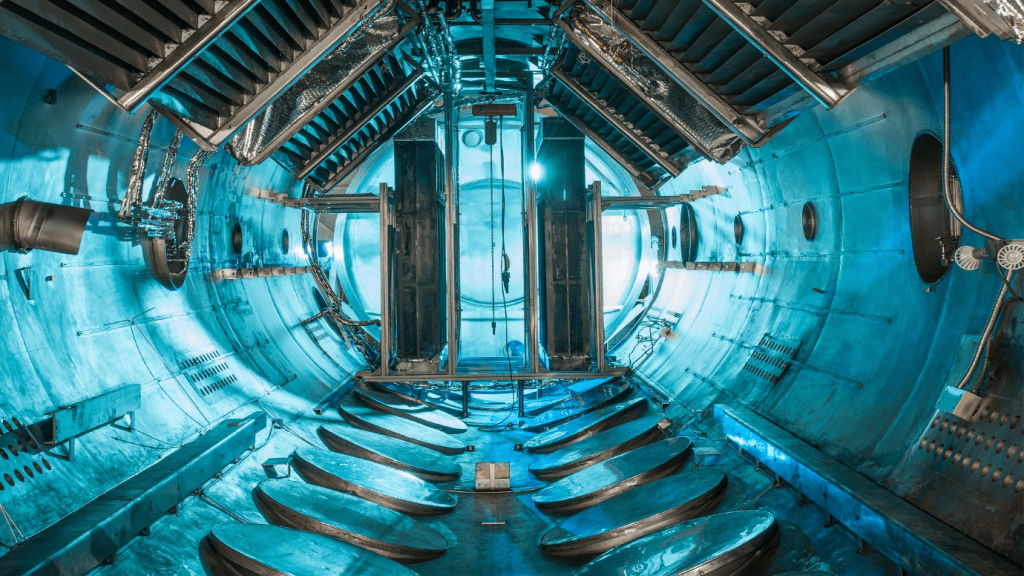

NASA holds agreements of each structure for the most expensive parts of its lunar Artemis program: The Space Launch System (SLS) rocket and Orion capsule designed to take astronauts to the moon’s orbit, under cost-plus contracts, and SpaceX’s Starship rocket to carry the astronauts to the lunar surface, under a fixed-price deal.

NASA has awarded numerous multi-billion dollar cost-plus contracts to various contractors to develop SLS and Orion, primarily to Boeing, the lead contractor building SLS; Lockheed Martin, leading Orion development; and Northrop development Grumman, supplying the rocket’s boosters.

Since 2012, NASA has spent $20 billion to develop SLS, and more than $12 billion on Orion, according to the agency’s Inspector General. And, not including development funding, the cost of each SLS launch has ballooned eightfold since 2012: From $500 million to $4.1 billion, with the rocket’s debut delayed five years and counting.

By comparison, NASA has had steady success with major fixed-price contracts. Under Commercial Crew, the agency awarded SpaceX nearly $3.1 billion and Boeing nearly $4.8 billion for the past decade to develop spacecraft to deliver astronauts to the International Space Station.

We provide the insights on leaders who are responsible for taking their organization to new heights, all the while bringing together a group of talented individuals.

June 09, 2025: Canada has issued an international appeal for firefighting support as wildfires intensify across multiple provinces

May 27, 2025: Air Canada Cuts Five U.S. Routes for Winter 2025–26, Part of Broader Cross-Border Retrenchment

May 26, 2025: Trump Freezes $2.2B in Federal Grants to Harvard Over DEI, Threatens Tax-Exempt Status.

May 14, 2025: Microsoft has announced plans to reduce its global workforce by approximately 3%, affecting roughly 10,000 employees across multiple departments.

May 13, 2025: The Trump administration is considering suspending the constitutional right of habeas corpus in a bid to accelerate mass deportations.

April 29, 2025: Donald Trump’s second term has reached the 100-day mark under sustained public skepticism, with national approval ratings