Canada Appeals for International Firefighting Aid

June 09, 2025: Canada has issued an international appeal for firefighting support as wildfires intensify across multiple provinces

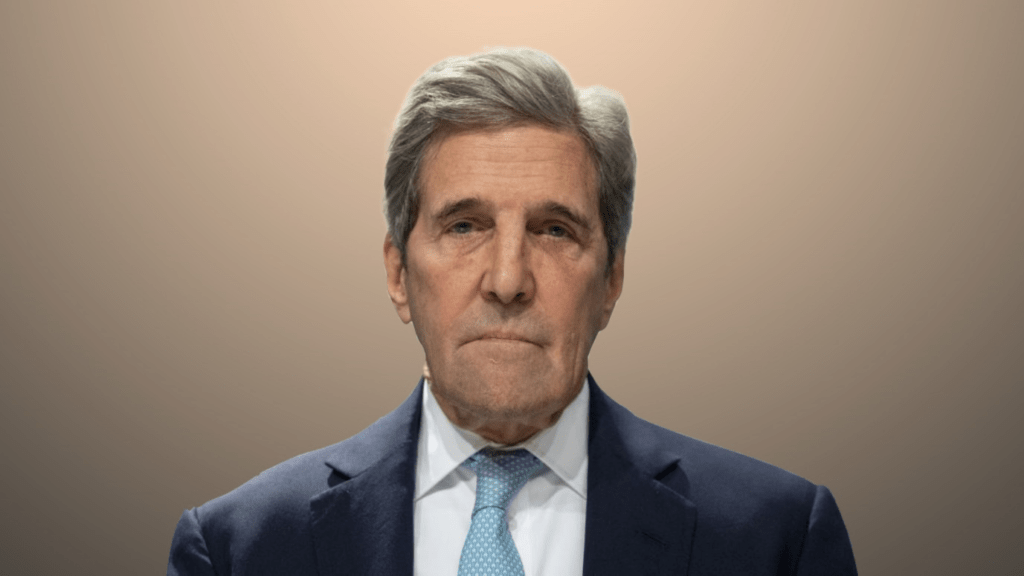

September 01, 2021: -On Tuesday, U.S. climate envoy John Kerry was in Tokyo to discuss efforts to fight climate change with top Japanese officials ahead of a United Nations conference back in November.

Kerry was scheduled to meet with P.M Yoshihide Suga, Foreign Minister Toshimitsu Motegi, Environment Minister Shinjiro Koizumi, and Economic, Trade, and Industry Minister Hiroshi Kajiyama.

On Monday, Kerry arrived in Japan and will fly out to China for more climate talks on Tuesday evening, his second trip to the country under President Joe Biden’s administration.

While talking to Koizumi, Kerry was expected to discuss decarbonization efforts and cooperation between the two countries ahead of the U.N. climate conference, known as COP26, in Glasgow in the first half of November.

During a visit to London in the previous month, Kerry called on global leaders to work together and accelerate actions needed to curb the increasing temperatures to no more than 1.5 degrees Celsius in the pre-industrial levels. He urges China to join the U.S. in cutting carbon emissions urgently.

China is the world’s top carbon emitter, followed by the United States. Japan is fifth.

Most of the countries have pledged to eliminate net carbon emissions by the year 2050. Japan has promised to reduce its emissions by 46% from 2012 levels, up from the target of 26%, to achieve carbon neutrality by the year 2050. China has also set a goal to hit carbon neutrality by 2060.

Suga has said Japan would try to push the reduction as high as 50% to align with the European Union.

Japan’s Environment Ministry seeks a significant budget increase to promote renewable energy and decarbonizing programs to achieve that target. The Trade and Industry Ministry plans to use large subsidies to promote electric vehicles and wind power generation, according to a draft budget proposal for the year 2022.

In its draft basic energy plan released in July, the Trade and Industry Ministry said the share of renewables should be raised to 36% to 38% of the power supply in 2030 from the present target of 22% to 24%. The plan maintains the present 20% to 22% target for nuclear energy as officials remain undecided regarding what to do with the nuclear industry that is struggling since the 2011 Fukushima disaster.

In his Sept. 1-3 China visit, Kerry is expected to meet with his Chinese counterpart, Xie Zhenhua.

We provide the insights on leaders who are responsible for taking their organization to new heights, all the while bringing together a group of talented individuals.

June 09, 2025: Canada has issued an international appeal for firefighting support as wildfires intensify across multiple provinces

May 27, 2025: Air Canada Cuts Five U.S. Routes for Winter 2025–26, Part of Broader Cross-Border Retrenchment

May 26, 2025: Trump Freezes $2.2B in Federal Grants to Harvard Over DEI, Threatens Tax-Exempt Status.

May 14, 2025: Microsoft has announced plans to reduce its global workforce by approximately 3%, affecting roughly 10,000 employees across multiple departments.

May 13, 2025: The Trump administration is considering suspending the constitutional right of habeas corpus in a bid to accelerate mass deportations.

April 29, 2025: Donald Trump’s second term has reached the 100-day mark under sustained public skepticism, with national approval ratings