- February 13, 2026 10:04 am

- California

Additive manufacturing, commonly called 3D printing, has revolutionized the manufacturing industry by offering unprecedented design flexibility, customization, and speed. Unlike traditional methods that involve subtracting material from a raw block to create a finished product, additive manufacturing builds products layer by layer using materials such as polymers, metals, ceramics, and composites. This technology has not only made production faster, but it has also allowed for the creation of intricate geometries that were once impossible to produce using traditional manufacturing methods. In this article, we will discuss the role of additive manufacturing in the production process.

Design Flexibility

One of the most significant advantages of additive manufacturing is its design flexibility. The technology allows designers to create complex geometries that would be impossible or extremely difficult to produce using traditional methods. Additive manufacturing eliminates many constraints that designers face when working with traditional manufacturing methods, such as the need for specialized tooling and the difficulty of creating complex shapes. This flexibility allows designers to create products optimized for performance and functionality rather than being limited by manufacturing constraints.

Customization

Another advantage of additive manufacturing is its ability to produce customized products quickly and efficiently. With traditional manufacturing methods, customization often requires significant tooling changes and reprogramming, which can be time-consuming and expensive. Additive manufacturing eliminates this limitation, making producing customized products on demand easy. This flexibility is especially beneficial in industries such as aerospace, where customized parts are often required to meet specific performance requirements.

Speed

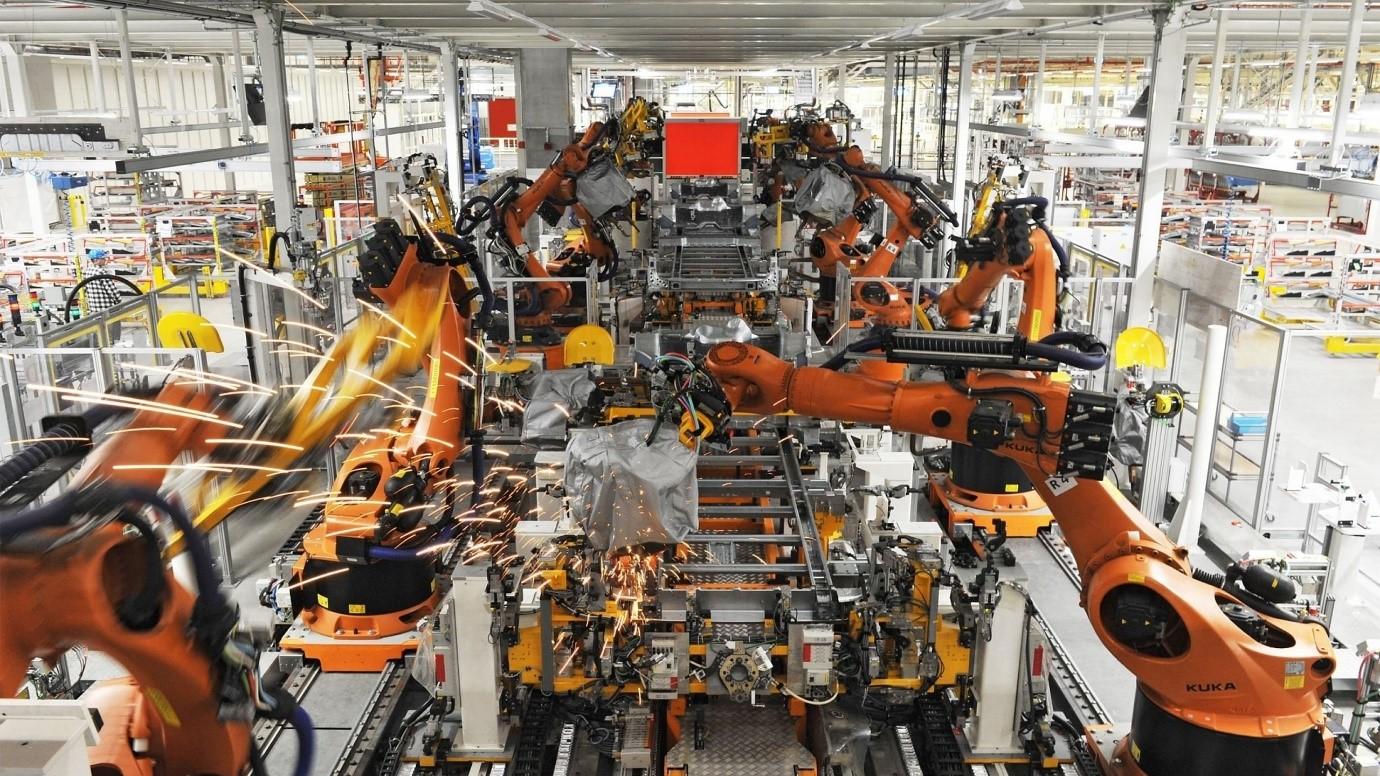

Additive manufacturing is also incredibly fast compared to traditional manufacturing methods. Because products are built layer by layer, there is no need for specialized tooling or multiple production steps, which can significantly reduce production times. This speed is particularly useful in industries such as automotive, where quick turnaround times are essential for keeping up with market demand.

Reduced Waste

Another significant advantage of additive manufacturing is its ability to reduce waste. Traditional manufacturing methods often produce significant amounts of scrap material, which can be costly and environmentally damaging. Additive manufacturing eliminates this waste by only using the material needed to produce a product. Additionally, many additive manufacturing technologies can recycle leftover materials, reducing waste.

Applications

Additive manufacturing has applications in various industries, from aerospace and automotive to healthcare and fashion. In aerospace, additive manufacturing creates lightweight, high-strength parts that meet specific performance requirements. In healthcare, additive manufacturing is used to produce custom prosthetics and implants. In fashion, additive manufacturing creates unique and customizable clothing and accessories.

Conclusion

Additive manufacturing has revolutionized the industry by offering unprecedented design flexibility, customization, speed, and waste reduction. This technology has made it possible to produce complex geometries, customized products quickly and efficiently, reduce waste, and create products optimized for performance and functionality. As technology advances, we can expect additive manufacturing to become an even more integral part of production.